Applications

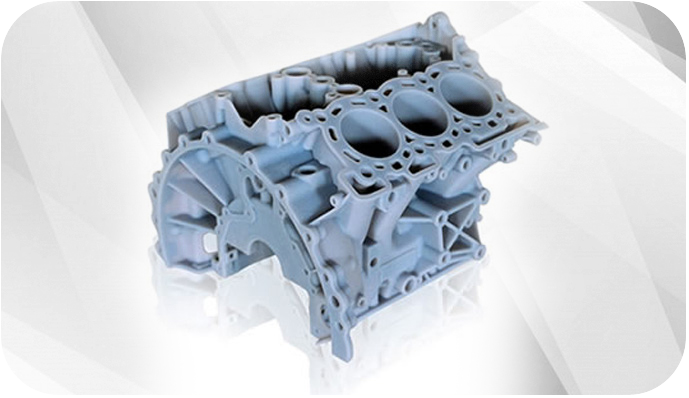

AUTOMOBILE

Leading global companies have recently begun to realise the commercial benefits of 3D printers in automotive manufacturing beyond prototyping. 3D printing has significantly transformed the way automobiles are designed, developed, and manufactured. 3D printers in automotive manufacturing and design can offer global automobile manufacturers the following benefits.

Rapid Prototyping:

One of the major benefits of 3D printers in automotive design is the empowerment of rapid prototyping in the pre-manufacturing stage. Companies have the possibility of developing everything ranging from scale-models right down to individual component, faster than ever. Prototyping in-house allows businesses to control any Intellectual Property (IP) infringements and information leaks.

Lower Turnaround Time:

Time saved in the prototyping stages drastically reduces turnaround time across all subsequent stages of manufacturing. This adds great business value in terms of lower costs and added agility.

Low Consumption and Wastage:

3D printing in automotive design drives lower consumption and wastage unlike the traditional approaches of vehicle design. Learnings from this can be effectively leveraged in reducing consumption and wastage of materials in all subsequent manufacturing stages.

Lower Costs:

Time and resources saved in the various stages of production reduces overall cost of production. Lowering costs at every level allows companies to transfer some of the cost-reduction benefits to the end-user.

Added Flexibility:

3D printers in automotive design empowers companies to try multiple options and iterations right in the development stages, leading to optimum and efficient automobile design. Manufacturers have the agility to make design changes on-the-fly helping them stay in-tune with market requirements and ahead of competition.

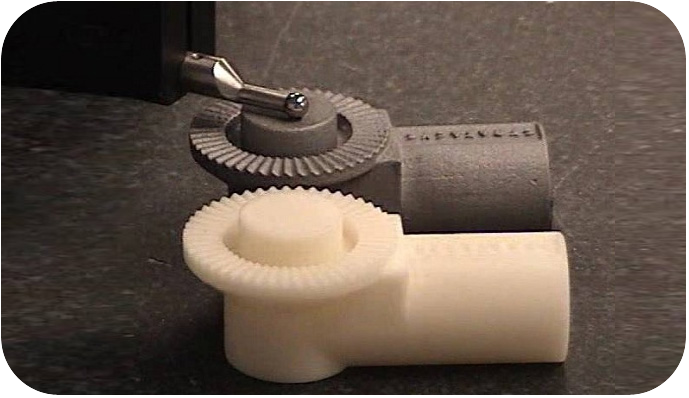

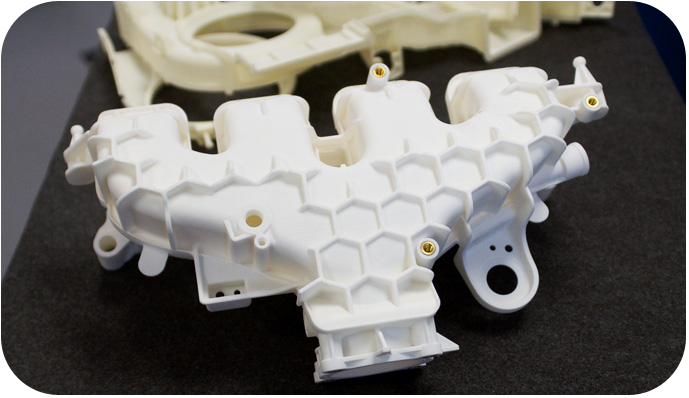

MOULDS / TOOLS / FIXTURE

Shaping the way forward

Most industrial manufacturers are aware of the tedious and time-consuming nature of pattern casting in the production cycle. Apart from this, pattern casting is labour-intensive and subject to higher tolerance variations. New-age 3D printed pattern casting can help solve these production challenges. Sand casting patterns can be 3D printed easily with PolyJet or FDM Technology.

3D printed pattern casting can be used in foundries or in-house, depending on your production requirement. 3D printing also offers savings in labour, cost, and time, faster product development and can act as a tool for low-volume production.

Benefits of 3D Printed

Leading manufacturers and foundries have already harnessed the benefits of 3D printed pattern casting. By simplifying the tooling and cast making process, 3D printing systems are gradually moving from prototyping to low-volume production roles. 3D printed pattern casting can offer the following benefits

Time and Cost Efficiency: As tooling costs are eliminated, 3D printing becomes an economical alternative to conventional pattern casting processes. Time saved in this stage empowers faster production-cycles and increases overall efficiency.

Lower Turnaround Time:

Time saved in the tooling and casting stages drastically halve the turnaround time across all the subsequent stages of manufacturing. This adds a great business value in terms of lower costs and added agility.

Increased Accuracy:

The output quality of the 3D printed pattern casting is highly-accurate with the lowest tolerance variations. In a production scenario, there is reduced wastage and minimized post-processing work for unfinished cast parts.

Added Agility:

3D printed pattern casting empowers multiple pattern casting options. This allows manufactures to stay agile, make changes faster and lead the way to optimum and efficient design. 3D printers can also double-up as a tool for low–volume production.