Services

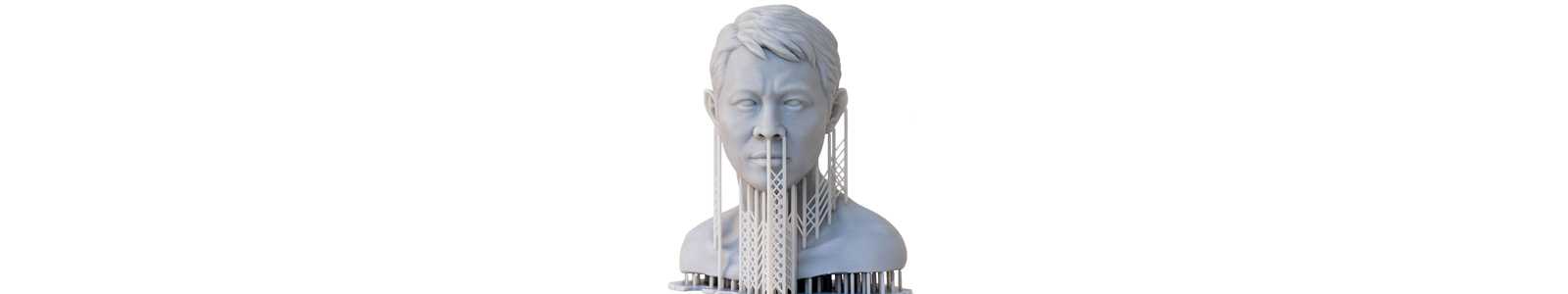

To Create Prototypes :

3D printing enables designers to skip the fabrication of tools and go straight to finished parts. And although printing a prototype part might take several hours, it is still significantly faster than building tools that are then used to fabricate prototype parts. This ability to quickly fabricate prototypes enables engineers to validate design concepts faster, speeding up the overall development process.

To Design Concepts & Mock-ups:

Design and manufacturing engineers can use these prototypes as a tool to better communicate how a design looks, feels, and operates allowing for the product design to integrate with manufacturing at an earlier stage in the development lifecycle. "The defense industry has printed the silhouettes of planes that are used on the mock-up of the flight deck to keep the flight deck organized", Said Adm. James Winnefeld, vice chairman of the Joint Chiefs of Staff.

To Build Satellite Brackets

Additive manufacturing allows engineers to create complex brackets that are able to fit inside small spaces. Instrumentation, such as sensors, can then be added. "You need a lot of design functionality for a really tight little space in a satellite where every square inch and every pound in a satellite costs an enormous amount", said David Dietrich research and technology lead engineer for additive manufacturing in metals

Manufacturing

In mould making we used computer controlled equipment for the actual manufacturing of the moulds. We have expertise in manual machining, CNC machining, CNC wire EDM, CNC Ram EDM, surface grinding, hand polishing and more. The majority of parts that are in existence today are made using moulds. We also provide injection moulding and blow moulding services.

For Small-Volume Production:

Certain low-volume, weight-sensitive products are opening up additional opportunities for 3D printed parts. Satellites and launch vehicles, for example, require intricately designed parts to reduce weight and minimize packaging space. Many of these parts are produced in very small quantities and are very expensive to fabricate using traditional machining or injection molding technologies. In many cases, these kinds of parts can be fabricated more quickly and cost-effectively than via traditional processes.